Tensile property evaluator: Ferrous metal, polymer and composite

This section presents the key objectives, features and the operational manual of the software. It is recommended to go through this before starting with the software. If you have already read it, kindly skip to the bottom of the page to continue with the software.

Tensile properties of materials are hard to predict and requires physical tests to be performed. These physical tests are destructive in nature, therefore material wastage in the form of specimen failure is obvious. The process also consumes a lot of energy and requires high degree of calibration for an accurate result. In overall, evaluating tensile properties of materials is a costly affair accompanied by loss of resourceful time.

Key objectives:

- This software is our first attempt to address these issues of tensile property evaluation by incorporating state-of-the-art prediction models validated by researchers all across the globe.

- The software employs both analytical and empirical approaches in their prediction models for different types of steels and polymers to give a robust measurement of their tensile properties.

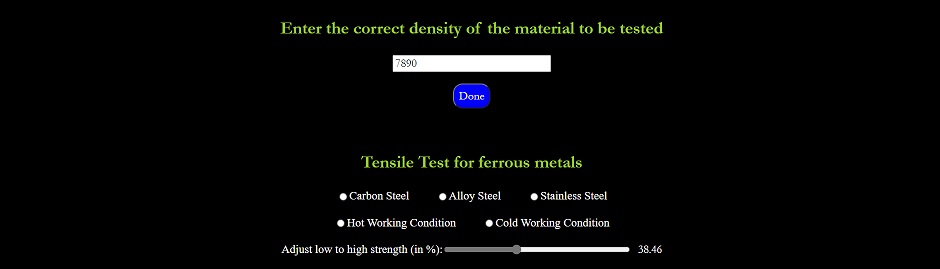

- The software is aimed at giving approximate results of the tensile properties of the material the user desires to test based on the density of the material and few other simple parameters as in varying the ‘low to high strength’ slider control in case of steel for different arbitrary grades of steels.

- The software is aimed at giving visual representation of the tensile properties in the form of graphs and tables and can be used as an educational tool or as a tool for independent designers in selecting materials before actually going for any product design.

- The software is made ‘easy to understand’ and simple for users with / without any technical background by incorporating minimum user inputs and commonly used terms.

Key features:

- The software has an user interactive / friendly interface with recommendations provided in case of any input error at every step.

- The software incorporates mainly carbon steels, alloy steels, stainless steels and engineering polymers with few varieties of steel-polymer and polymer-polymer composites.

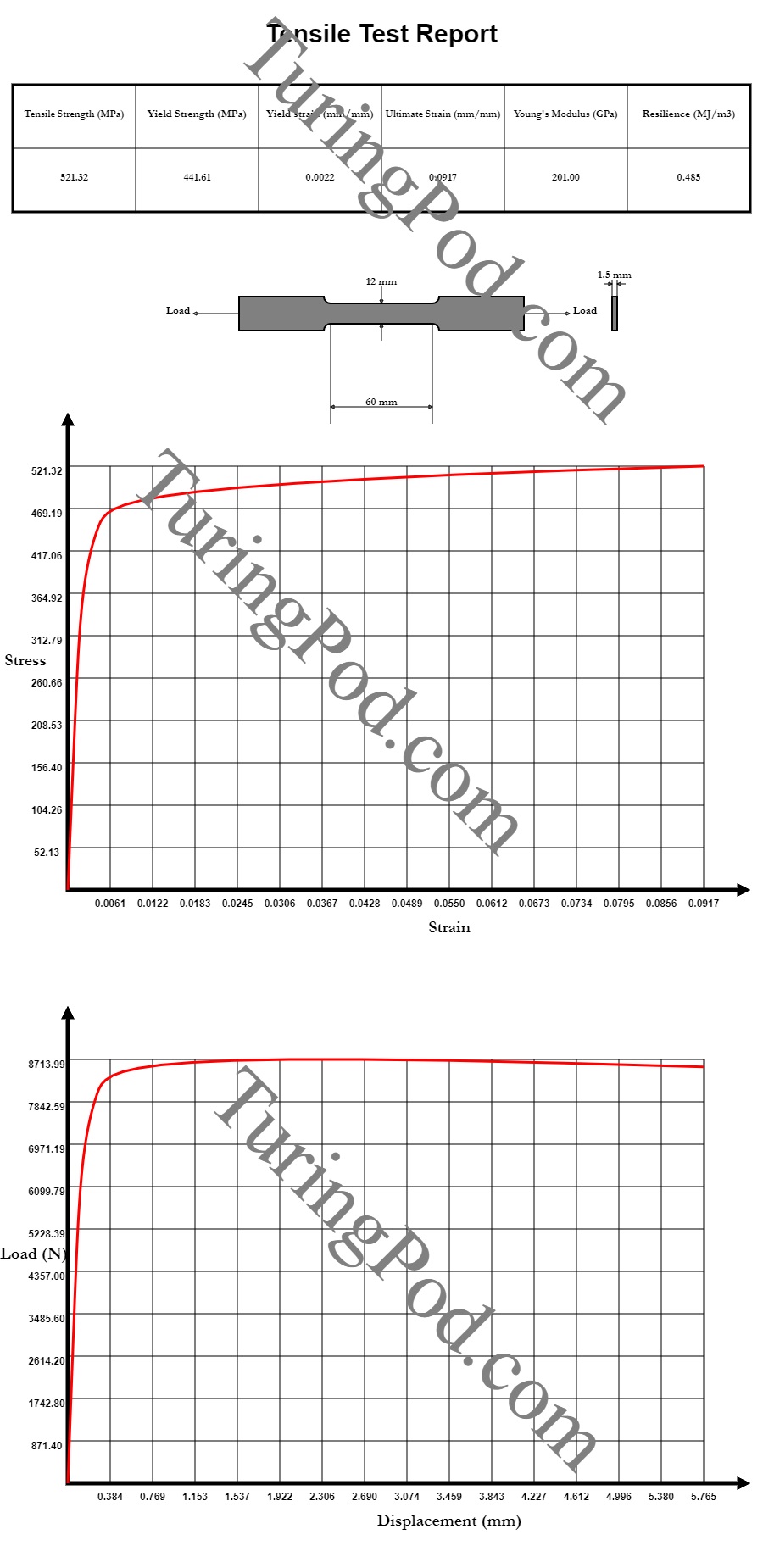

- A tensile report is generated after evaluation which provides visual representation of the stress – strain and load – displacement relationships in the form of graphs and the property values presented in a table.

- The generated report is downloadable in pdf format with no in-text watermarks for subscribed users.

- The working condition (hot or cold) and the ‘low to high strength’ slider value along with the type of steel chosen generally determine the tensile properties of steels while in case of polymers, the density is solely responsible in determining its tensile properties.

- In case of composites, not all combinations of fibre-matrix materials have been incorporated and only the combination of steels and polymers already included in the software have been used as fibre-matrix material.

- The fibre density and fibre volume fraction generally determine the tensile properties of composites which in normal circumstances lie within the limits of the two extremes: isostress and isostrain conditions. The user can select both the conditions or just one condition to be displayed in the tensile test report.

Note: The density values must be put appropriately in case of polymers for more accurate determination of tensile properties. The density values of steel ranges between 7500 to 8500 kg/m3, of polymers ranges between 50 to 2200 kg/m3 and of composite ranges between 500 to 3100 kg/m3.

Note: All the tensile test evaluations have been assumed to be carried out at a room temperature and at quasi-static strain rates. Also, the stress-strain, load-displacement plots have been extended upto the ultimate tensile strength and not beyond necking of the material.

Cold worked Carbon Steel Tensile Properties, Source: Tensile Property Evaluator output generation

Manual:

- Login with your email id and password and then register for free trial. Click on the ‘continue free trial’ button and you will be re-directed to the software.

- In the software, you will first need to enter the density value of the material to be tested and then click on the ‘Done’ button.

- Based on the density value, the software will automatically detect the material class and display the desired tensile test box for steels, polymers or composites. In case the density value matches the ranges of both polymers and composites, another box appears for the user to choose between the two, whichever the user was referring to.

- In the ‘tensile test of steel’ display box, the user needs to select the type of steel, working condition (hot or cold) and adjust the desired strength in terms of percentage on the 'low to high strength' slider scale. After making all the selection, the user can press the ‘Evaluate’ button to generate the tensile test report.

- In the ‘tensile test of composites’ display box, the user needs to enter the values for fibre density, fibre volume fraction percentage, select the fibre type and the fibre alignment condition (iso-stress or isostrain). After entering and selecting all the fields, the user can press the ‘Evaluate’ button.

- In the ‘tensile test of polymers’ display box, the user can simply press the ‘Evaluate’ button for tensile test report generation.

Note: In case of any errors in input values, the software will recommend the range of values within which the value must be entered.

Users are most welcome to provide any reviews / suggestions / recommendations to further improve the software

Developer